There are many elements to consider when selecting the proper components for a Wi-Fi front-end solution. Whether you’re the design engineer building the product, the procurement officer tasked with acquiring the desired parts, or the marketing expert announcing the features and benefits of your company’s devices to the world, you may have different priorities about which parts are chosen and why. In a perfect world, the priorities will all align, and everyone works together as a cohesive team. More often, however, the needs of a single department become the focus, and cross-functional department needs may not surface early enough to ensure components are selected that serve the overall business goals.

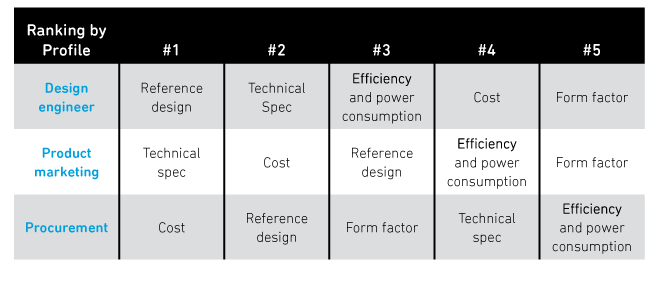

While it can be challenging to sift through the myriad of available suppliers looking for just the right components, there are 5 areas of key importance for each role to consider that may help narrow the field:

- Reference design

- Technical specifications

- Energy efficiency and power consumption

- Form factor

- Cost

We rank them by job function in the following table and then discuss them in depth below.

Areas of Importance by Job Function

1. Reference Designs

When choosing a vendor for your Wi-Fi front-end components, access to documentation such as reference designs, data sheets and S-parameters will greatly improve the design process, procurement feasibility and marketing of specific product features and benefits. Reference designs in particular are key as they provide PCB layouts, technical characteristics, system performance specs and full details of an existing front-end design. For engineers, these offer an excellent starting point for plug-and-play solutions or adjusting components as needed to fit specific internal requirements. Good designs also include important subtleties like software needed for power calibration, optimization and validation.

From a procurement perspective, reference designs provide confirmation that the parts being purchased can do what they’re supposed to do, have met the required specifications and are compliant with regulations. They should also include a bill of materials (BOM) for the referenced layout, and some companies even offer interactive software to show how adjustments for variations in performance will affect costs.

When it comes to marketing, reference designs go a long way in providing needed details around end-product specifications that can translate to user benefits. Improved power efficiency for extended battery life, or lower thermal output can be highly useful sales points. Additionally, reference designs offer insight into a competitor’s product that can provide great options for adding market differentiation.

Using reference designs from a highly reputable source like Qorvo can improve time-to-market by providing a known working circuit, layout, and BOM as a key starting point. However, use caution with designs from less-well-known suppliers as they can add unnecessary constraints, potentially lead engineering teams astray, or trap designers into expecting a layout will work only to find out it doesn’t which then requires additional expense to start over.

2. Technical Specifications

Component performance parameters such as Tx output power and linearity (error vector magnitude (EVM) floor) are extremely important when deciding on which elements to use in a Wi-Fi front end design. Technical specifications provide guiding metrics on how an RF layout will perform and should be clear and simple to understand. In order to procure components that meet the exact needs of the proposed design, both engineers and purchasing agents should be aligned on the technical requirements and know what can possibly be substituted if a specific part can’t be found. Listed on an RFP/RFQ (Request for Proposal/Request for Quotation), technical specifications act as the basis for an entire RF design and finding suppliers that provide detailed documentation, along with easily accessible technical support, is an important part of choosing where to buy wireless components.

In addition to the engineering and purchasing implications, specification documents are highly useful for product marketing managers as they help inform key differentiated performance attributes. They also define how these performance parameters directly relate to and benefit the overall solution and can be used not only to market a finished product, but to communicate back to engineering what end results are desired from a new design. Knowing exactly what a device can do for consumers, and how those capabilities compare to other devices on the market, impacts pricing strategies and brand positioning as well.

Manufacturers like Qorvo provide technical specifications for a variety of transmission rates and system configurations and have technical experts to answer questions and provide design support as needed. When looking for a supply partner, be sure to vet the ease of access and availability of technical specifications. A good vendor partner should always have the specifications at hand and be eager to support requests for design help.

Have a technical question on a Qorvo product? Visit our Applications section for relevant information about our Wi-Fi solutions.

3. Efficiency and power consumption

Today more than ever there is increased pressure to do more with less – packing added performance into smaller and smaller packages. There are many design challenges that accompany these requirements and selecting a FEM with high efficiency and low power consumption is a particularly important part of building successful Wi-Fi solutions. The right FEM can save time-to-market and add to cost savings in an overall system. Thermal management can be a critical expense for a wireless device, especially in 4x4 or 8x8 designs. Wi-Fi performance degrades when system temperature rises, and the cost of managing these temperature increases can build rapidly if not effectively managed.

For engineers, finding the smallest parts with the highest efficiency, lowest power consumption and best thermal management can be a big hurdle, but choosing a component that checks all of these boxes will pay dividends in improved performance and lower overall solution costs. With high efficiency FEMs, PCB size can often be reduced by an average of 15%. And without the need for added fans, heat sinks or additional tuning, design layouts can be simplified and accomplished much quicker.

While individual FEMs may not be the least expensive components on the market, increased integration has a direct impact on lowering overall system-level costs which procurement should keep in mind to improve product margins. The ability to source a single part from one supplier also makes accounting and managing the supply chain much less complicated. When choosing an appropriate supplier to purchase from, be sure to confirm their supply far enough into the future to ensure production needs are well accounted for. Those vendors that offer scalable solutions to grow or shrink with the market will be important allies in mitigating unwanted supply surpluses or shortfalls.

For product marketers, time-to-market is a key factor and more integrated parts like FEMs go a long way to reduce overall build times. Additionally, knowing that smaller, sleeker products can be created adds a competitive advantage in the demanding Wi-Fi market where a little less power used per device can result in big wins with clients whose power-consumption habits may be under increased scrutiny.

Consider Qorvo’s Front End Module solutions. Designed for the Wi-Fi needs of today, they provide high efficiency and low power consumption, allowing up to 25% reduced power dissipation which enables compact fan-less and ventless box design.

4. Form Factor

As described above, today’s Wi-Fi devices are becoming smaller and smaller but still require the same, or better, performance that consumers have become accustomed to. So, form factor is a major consideration when determining which components to use in a wireless design. Choosing highly integrated parts like FEMs and iFEMs (which include BAW filtering) supports reductions in package size and the need for extraneous or redundant parts. FEM manufacturers like Qorvo can often provide similar or better performance in their smaller form-factor parts, allowing for more product design flexibility. Purchasers appreciate the lower BOM provided with added integration and product marketers applaud the sleek design that reduced size can bring. Along with these benefits, using higher levels of pre-packaged, plug-and-play, fully integrated components saves much needed time and energy for design engineers attempting to fit so much performance in such a small package.

Qorvo Front End Modules cover a wide basis of both market standard form-factors and unique, highly integrated options in terms of size and solution features, which provide customers additional choices in their end product configurations. To Qorvo “Small is Beautiful,” and we strive to have options that enable product differentiation for our customers.

5. Cost

Managing budgetary concerns is always a balancing act. While there are numerous ways to cut costs, it’s important to know the needs of each department so that cuts can be distributed effectively, and key performance requirements are still met within budget. Taking a systems-level, holistic approach to mitigating cost means looking for areas to get more use out of dollars spent. For engineers, choosing highly integrated parts (like the aforementioned FEMs) and high-quality components may cost more on a part-by-part basis, but will add to overall savings as a lower BOM is realized. For purchasers, choosing a supply partner that offers scalability, predictability and reliability can go a long way in providing savings lost in unmet production timelines or redesigns due to component shortages. For product marketers, lower production costs offer additional flexibility in pricing structures where saving the consumer a few dollars on an individual unit can result in making additional profits from increased sales volume. The most important consideration when pricing components and choosing a vendor is quality. A quality supply partner will deliver high-end parts, on time, consistently and provide additional areas to work toward improving process efficiencies together.

Qorvo provides such high-quality solutions, capitalizing on our front-end differentiators, focusing on reducing power consumption and interference resolution, while maintaining high throughput and range in our components. We create the most efficient solutions, providing reliable coverage in competitive form factors.

We hope the five areas outlined above provide a helpful guideline for locating, choosing and designing the best front-end solutions. Each of these topics is important by itself, but when considered together, they provide for a much more effective Wi-Fi component sourcing strategy. When procurement, marketing and engineers can approach the design process together from a cross-functional perspective, there is greater success in achieving business goals and creating impressive products that make an impact.