In the Wi-Fi world, one of the most critical design challenges that engineers need to address is product temperature.

Wi-Fi components within routers and access points are typically subjected to average temperatures of 60°C (140°F) or greater, even when the room temperature is a moderate 25°C (77°F). It’s important to consider this fact early on in Wi-Fi product design, to help minimize redesign issues and additional costs. Let’s examine some of the biggest impacts of temperature on component performance, as well as strategies and specific RF products for overcoming thermal challenges in Wi-Fi front-end designs.

An evolving Wi‑Fi ecosystem

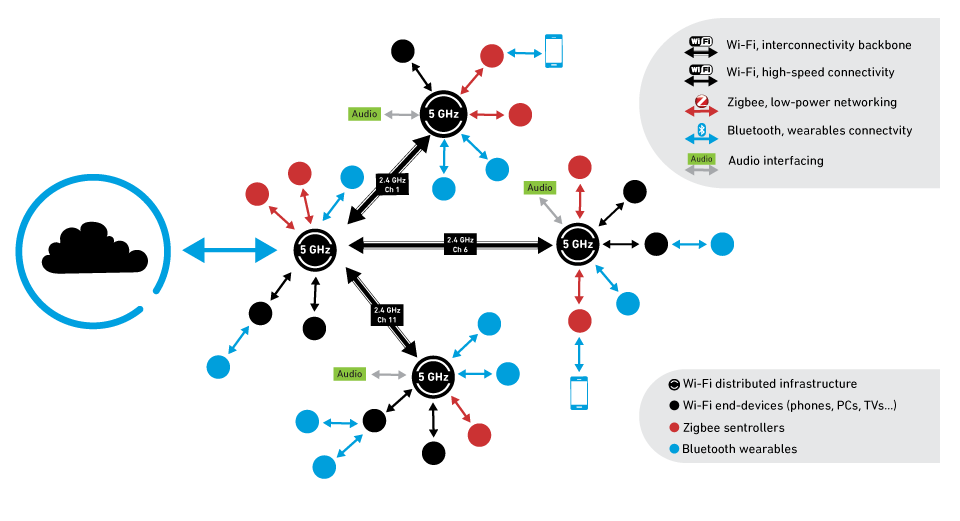

Heat is always an issue in Wi-Fi access points and routers, and the challenges are increasing as the wireless ecosystem becomes more complex (Figure 1). Several trends contribute to the thermal challenges:

- More users on more Wi-Fi channels: Today’s access points and nodes support up to eight 2.4 GHz and eight 5 GHz paths, and they have to support more devices and users than ever before.

- Shrinking size and expanded functionality: Wi-Fi hardware continues to pack more capabilities into a smaller product footprint, especially in many distributed Wi-Fi/mesh products.

- Wi-Fi 6, the next Wi-Fi generation: With Wi-Fi 6 (802.11ax), the processor has to work harder to support more complex modulation schemes, higher data rates and greater throughput. This produces more heat and increases the risk of poor RF front-end (RFFE) performance.

- Support for the Internet of Things (IoT): Some Wi-Fi units now include even more wireless radios to enable support for IoT devices that communicate via Zigbee, Bluetooth, Bluetooth Low Energy (BLE) and Thread.

These trends lead to an increased number of RF chains in the Wi-Fi front-end, increasing the heat within the unit. The problem is especially acute when the unit is the same size or even smaller than previous generations. This increase in unit temperature also increases the RF tuning challenges.

In short, more functionality and more data throughput in a smaller product footprint all contribute to the same problem: more heat.

Figure 1. Distributed Wireless Indoor Architecture with a Pod in Every Room

How heat impacts Wi-Fi RFFE components

Heat can degrade overall system performance, impacting throughput, range and the ability to prevent interference. So, when designing Wi-Fi systems, it’s important to choose RFFE components that mitigate heat-related problems.

- As devices transition from 802.11ac to 802.11ax, more-efficient components will be needed to minimize the heat produced.

- Designers should consider using a fully optimized, integrated front-end module (FEM) instead of discrete front-end components. This reduces line lengths and the need for additional tuning components, which contribute to insertion loss.

Temperature primarily affects the following RFFE components:

- Power amplifiers (PAs)

- RF switches and low noise amplifiers (LNAs)

- Filters

Here are some of the heat-related design challenges for each type of component:

Transmit Chain: Power Amplifiers

- The PA pulses on and off due to Wi-Fi time division duplexing (TDD) operation, increasing PA transients that contribute to heat problems.

- The PA has to meet tighter linearity/EVM specifications with Wi-Fi 6 (802.11ax), to support 1024 QAM modulation.

- Higher-order modulation with Wi-Fi 6 also makes the processor work harder, generating more heat.

- The efficiency of the PA degrades as insertion loss within the RFFE increases. Poor RFFE performance also means the processor has to work harder to meet overall system requirements.

Design Tip:

Use optimized, highly linear PAs or FEMs.

Receive Chain: Switches / LNAs

- Switches: Higher insertion loss in the switch means the PA must work harder to compensate, generating more heat.

- LNAs: Heat degrades the noise figure (NF) and can drastically reduce throughput.

Design Tip:

Use LNAs with a lower NF and high-linearity, low-loss

switches.

Filters

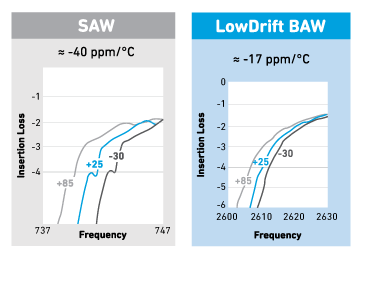

- Filters tend to drift as the temperature shifts. This can result in high insertion loss at band edges, which could cause a low gain or POUT response from the RFFE.

- If the filter drifts too much, the PA pushes more power output to compensate for the insertion loss, generating more heat.

- Surface acoustic wave (SAW) filter technology has inherently greater drift and insertion loss than bulk acoustic wave (BAW), and is less effective at Wi-Fi frequencies.

Design Tip:

Use BAW filters to minimize insertion loss and

temperature drift.

Qorvo Wi-Fi solutions for managing heat: Tx and Rx FEMs

With each new product generation, Qorvo challenges its design teams to increase linear power without increasing power dissipation — to design devices that provide higher throughput with the same power consumption as previous generations. To help achieve this goal, many of our products are FEMs that integrate transmit and receive functions (Table 1). Using RF FEMs reduces line lengths, insertion loss and overall power consumption. FEMs also simplify RF design and reduce the total number of RF components.

Table 1. Qorvo Wi-Fi Solutions for Managing Heat

|

Part No. |

Description |

Functions |

Wi-Fi Standards |

Linear Power1 |

Dissipated Power |

|---|---|---|---|---|---|

|

2.4 GHz Wi-Fi FEM |

PA + SW + LNA |

Wi-Fi 5 |

+24.5 dBm |

1.8 W |

|

|

5 GHz Wi-Fi FEM |

PA + SW + LNA + CPLR |

Wi-Fi 6 |

+23 dBm |

1.45 W |

|

|

5 GHz Wi-Fi FEM |

PA + SW + LNA + CPLR |

Wi-Fi 6 |

+18 dBm |

0.78 W |

1 = POUT (typical) at MCS9 VHT80 -35 dB dynamic EVM

Qorvo Wi-Fi solutions for managing heat: Filters and iFEMs

Qorvo Wi-Fi filters use high-performance BAW technology, which provides lower insertion loss and temperature drift compared to SAW (Figure 2). In addition to our discrete filters, we provide integrated FEMs (iFEMs) that combine BAW filters with our active components. Integrating the filter into the module reduces the need for external tuning and provides a high-performance product that can accelerate time to market. Qorvo Wi-Fi products that use BAW filters include the following.

Discrete BAW filters:

- QPQ1907: 2.4 GHz Wi-Fi/Bluetooth/LTE Coexistence BAW Filter

- 885136: 2.4 GHz Wi-Fi Bandedge BAW Filter

iFEMs with integrated BAW filters:

- QPF7221: 2.4 GHz Wi-Fi iFEM with Integrated Coexistence BAW Filter

- QPF7219: 2.4 GHz Wi-Fi iFEM with Integrated FCC Bandedge BAW Filter

Figure 2. SAW versus BAW on Thermal Drift

Pick an RF partner that helps you beat the heat

With today’s Wi-Fi designs squeezing together so many radios and RF chains, it’s important to partner with an RF supplier that helps you meet linear power budgets while minimizing power dissipation to overcome heat challenges.

To find out more about Qorvo’s products for Wi-Fi applications, view our Customer Premises Equipment information online or contact Qorvo Sales.