Volkswagen Drives Production with UWB Operations

Challenge

Hundreds of thousands of automobiles are produced within VW Slovakia's complex manufacturing facility. At the heart of its future plans is the use of digitization to drive innovation. One way was to employ a Real Time Location System (RTLS) that could optimize fleet utilization; provide reliable connectivity within the factory's metallic environment; handle high traffic density; and provide ongoing visibility.

Solution

The key decision for the solution was finding the right location technology. Ultra-Wideband (UWB) has proven to be both very accurate and extremely reliable even when used within metallic industrial environments. Qorvo's UWB technology can cover large areas with far fewer access points/anchors than competing technologies - 99.98% reliability.

In addition, UWB provides a fast refresh rate of 333 milliseconds, enabling continuous track and trace. And the low power draw of the UWB system delivers guaranteed long battery life of more than a year, decreasing the total cost of ownership.

Results

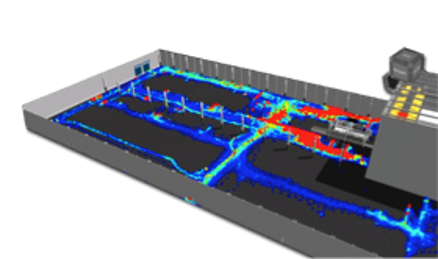

CEIT and Qorvo collaborated to deliver a UWB-based RTLS for VW Slovakia in only six months. After the system's launch, the new platform was already providing the data needed to increase the factory's utilization. The real-time overview of all movement included crucial operations data such as down and idle time, distance traveled, and each machine's efficiency.

As a result, optimizing layouts "expanded" the warehouse area by 20 percent without any construction; fleet travel distances were reduced by 10 percent; and increased visibility minimized stop times. Notably, any process updates were modeled first to ensure success.

Looking to the Future

Based on the results already delivered, the next steps might include expanding the system to other halls and adding new use cases. Those include the prevention of collisions by giving warning signals to the drivers, slowing down forklifts automatically at crossroads, tracking site visitors and employees for safety reasons, knowing exactly where every single person is in case of an emergency, etc.

Beyond important safety features, the system also allows for expanded asset tracking. Traceability of parts can play an essential role in quality control, while detailed knowledge of the exact location of parts can enable true "just-in-time/just-in-place" production, increasing factory floor utilization through reduced inventory at each work station.

The flexibility and scalability of Qorvo's UWB-based systems means that future use cases can be added without additional infrastructure and with minimal additional optimization.

About VW

Volkswagen, shortened to VW, is a German automaker founded in 1937 by the German Labour Front, known for the iconic Beetle and headquartered in Wolfsburg. The Volkswagen Bratislava Plant is an automotive factory and co-located test track in Bratislava, Slovakia.

Learn more about Qorvo's innovative UWB solutions.